- 推荐产品

- 更多>>

- MVR+FXGG Waste Water

- Lifting Film Evapora

- Forced circulation e

- Multi-effectfilmevap

- (MVR+FXGG)multifunct

- 产品展示

Applicable Scope:

1.Can be used under high or slight vacuum condition;

2.Distillation and fractionation on the high boiling point and high;

3.Can be used as concentration equipment for the material with high boiling point. high viscosity, high solid content and high thermal sensitivity;

4.Can be used as reactor the internal rotation shaft can be regarded as hollow stirrer .and can be used as reflux reactor For distillation, can be used as titration reaction for timely heating or cooling;

5.The circumstances that needs to inc『ease the concentration ratio to the maximum.

6.lt is widely used in fine chemicals. pharmaceuticals, light industry,foodstuff, alcohol. and beverage and environment protection areas.

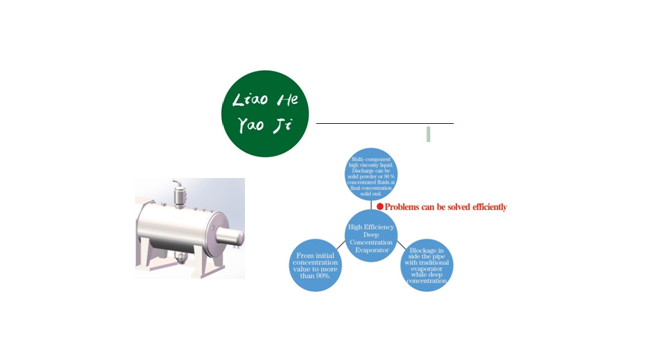

Technology Advantage:

1.Maximum concentration ratio (more than 30 times), maximum final concentration (90- 100%)

2. Achieves the maximum solvent recovery at maximum final concentration

3. Discharges solid directly through concentration equipment. the advantage of energysaving is also obvious.

Features:

1.Thin evaporation film will be formed on the internal surface of the equipment. no dead corner. no pressure drop, no resistance.

2. With same volume, able to achieve more than three times evaporation eff1c1ency compared to other evaporators.

3.Thermal efficiency is more than 90%.

4.The final concentration percentage is high, also even under high concentration circumstance, it is not easy to cause scale, especially applicable for high concentration circumstance,「educing the transportation and the later cleaning cost dramatically.

5.Solid is able to be discharged/produced directly for several special material.

6.Distillation or concentration operation can be continuous. hemicontinuous or discontinuous.

7.Working efficiency can be increased by 5%-15%, high recovery, good quality and no damage on the material.

8.Able to work either under normal pressure and 1OOPa-1Pa vacuum circumstance O「 WO「k as re-boiler under positive or negative pressure circumstance.

9.The cold hot agent is able to go through inside the internal hollow rotating components.

10.Overcome the defects as thick film. scaling or material mixing.

11.Small temperature difference, the evaporation can take place when the temperature equal to 5degree.

FXGG High Efficient Evaporator Specification:

Standard Model

FXGG1000

FXGG2000

FXGG3000

FXGG5000

FXGG6000

FXGG8000

FXGG10000

FXGG20000

FXGG550000

Volume

1000

2000

3000

5000

6000

8000

10000

20000

50000

Maximum Evaporation Volume (M3.h)

140

140

140

135

135

130

130

120

120

Heating

area Single pipe

9.5

14

25

35

40

46

62

/

Double pipe

/

35

48

54

62.5

84

100-360

150-500

Motor power(kw)

3 11

4-22

4 30

5.5 30

7.5 37

11 37

15 45

Material loading co-efficiency

0.3 0.5

0.3 0.5

0.3 0.5

0.3 0.5

0.3 0.5

0.3 0.5

0.3 0.5

0.3 0.5

0.3 0.5

Running type

Continuous, hemicontinous

Continuous

Net weight(T)

3.2

5.5

7.2

11.6

13.9

16.2

19.1

28

42

External Dimension (m)

3*1.4*3

4.1*1.5*3.2

5.2*1.7*3.5

7*1.8*3.8

7.3*1.9*3.8

8*2*3.8

9*2.俨3.8

10.2*2.7*4

14*3.2*4.6

Heating Substance

Hot water/steam

Primary steam or compressor

The condition for achieving the above data(1)Steam: 0.4MPa ; (2)Heated substance -water

one

one