- 推荐产品

- 更多>>

- MVR+FXGG Waste Water

- Lifting Film Evapora

- Forced circulation e

- Multi-effectfilmevap

- (MVR+FXGG)multifunct

- 产品展示

Application Scope

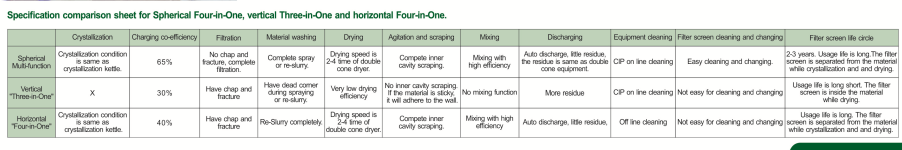

It is used in pharmaceutical and chemical products. It has the supreme advantage in the industry of production process for the flammables & explosives, hazardous & volatile and sterile raw active pharmaceutical ingredients which are difficult to be transferred from none-integrated equipment.

Customizable function based on customer`s requirements.

Structure working principal: Spherical Four In-One Equipment is consisted of

ball shape inner cavity and tilted rotor,

the inner

cavity and rotor are able to rotate independently.

Both rotor and

shell (cavity) are able

to be heated.

The cavity

is smooth and has no

dead angle achieving the maximum heating area and sufficient suction filtration area under the same

volume.

It has

good pressure resistance ability, no contamination to the material, high efficient. good hygiene condition and energy

saving. Through

PLC auto control

cabinet. it

is able to achieve rotate right and left, interval deoperation, stepless speed regulating and automatic

mate rral discharge.

Main features:

One equipment is able to replace the equipment such as crystallizer,centrifuge,

washer and

dryer with

the advantages of high efficiency,

low energy consumption, safe and

Eco-friendly. It has high mixing

capacity and initial chopping function.

While dynamic vacuum mixing drying process, the scrape and

agitating can

reach toeach places in the cavity,no blocking,

no pilling,

completematerial discharge, no

contamination of the material, the

inside of the machine is smooth without dead corner.It features with automatic material feeding

and discharge, on-line cleaning and sterilization, satisfying

new GMP

version

or FDA requirements.

one

one